Vertical Machine Building

-

Vertical Machine Building

Vertical Machine Building

Modern Precision is capable of research & development, and building vertical moulding machines in different types like 1K-/2K-/3K-vertical machines with multi workstations. With a multi-K moulding machine, different components in different colours can be moulded with different inserts just within one rotatory plate, so Modern Precision can meet your custom manufacturing requirements.

-

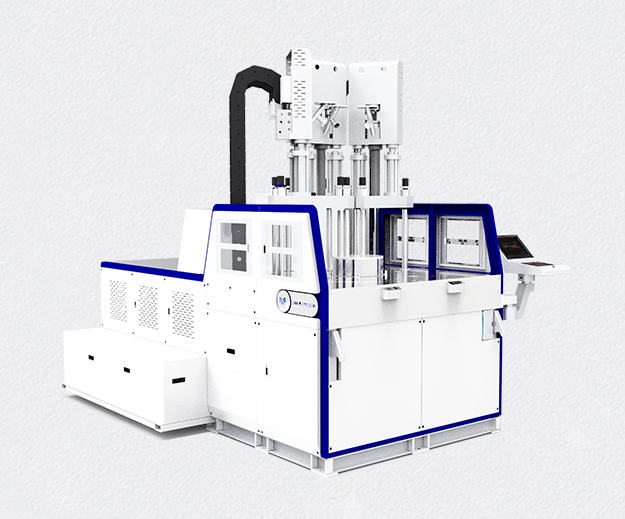

Vertical injection moulding machine (3K/6-workstation)

Vertical injection moulding machine (3K/6-workstation)Vertical injection moulding machine (3K/6-workstation)

1.Three injection moulding modules operate synchronously for insert moulding;

2.Different machines for different purposes are combined into one.

3.Three components (in different materials/colours) can be moulded into one by just one machine.

4.Injection modules for different plastics like SSR, LSR, etc. can be switched in place easily.

5.All data are recorded with MES + video networking system. -

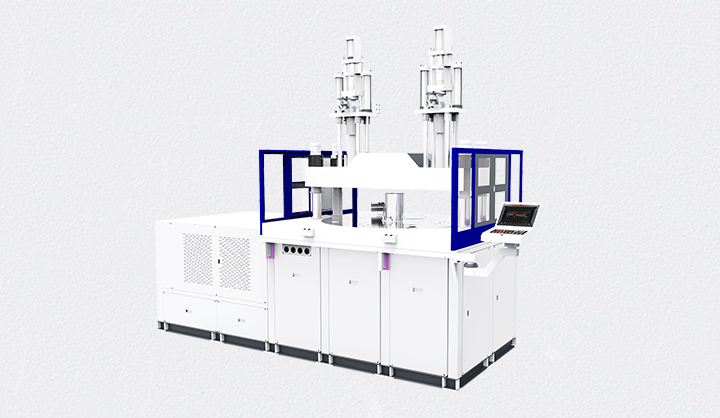

Vertical injection moulding machine (2K/4-workstation)

Vertical injection moulding machine (2K/4-workstation)

1.Inserting and moulding synchronously with 2 injection units;

2.Insert moulding esp. for products with FPC,wires like neckbands, AR/VR glasses, etc.;

3.Easy switch between injection units for different plastics like SSR, LSR, etc.;

4.All data record with MES + video networking system.

-

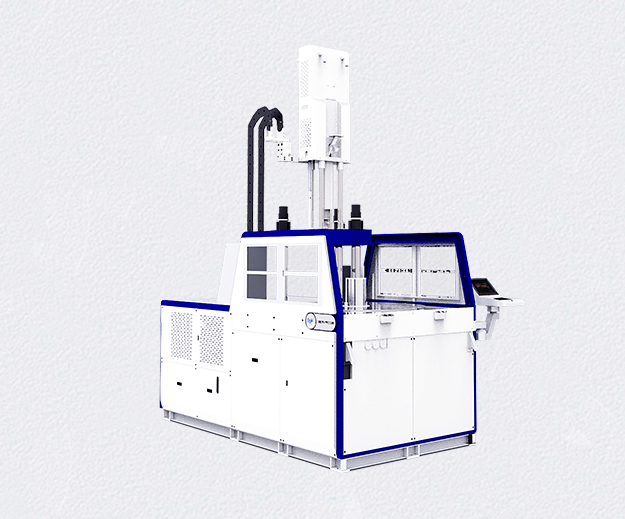

Vertical injection moulding machine (1K/6-workstation)

Vertical injection moulding machine (1K/6-workstation)Vertical injection moulding machine (1K/6-workstation)

1.Multi cooling stations to shorten freezing time and increase yield;

2.Multi workstations to ensure ramp-up and stabilize mass production;

3.Easy operation to insert in and take out parts;

4.Custom auto systems to assist auto moulding of intricate products.