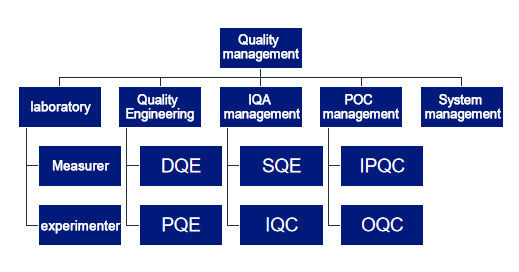

Quality Management

-

Quality System

Quality System

Modern Precision has a complete quality management system for moulding tools and moulded parts which has sequentially been granted ISO9001, ISO14001, IATF16949, ISO13485 certifications and will continuously be improved based on international standards. Modern Precision uses advanced quality control methods APQP/PPAP/CONTROL PLAN for FAI, CPK, CMK & PPK testing and analysis, controls and manages process digitally to maintain high quality, remain highly competitive and realize stable manufacturing.

-

Reliability Test

Reliability TestReliability Test

Modern Precision is equipped with a complete quality management system for moulding tools and moulded parts, advanced lab test devices to offer customers reliability testing like moulded-material analysis, environmental test, mechanical strength test, hazardous substance test, light aging test, corrosion test, etc. so as to satisfy requirements from customers on testing and quality.

Testing Equipment

-

Constant Temperature And Humidity Test Chamber

Constant Temperature And Humidity Test Chamber -

Manual Plane Measuring Projector

Manual Plane Measuring Projector -

OGP 3D Optical Measuring Equipment

OGP 3D Optical Measuring Equipment -

Articulated Arm Measuring Instrument

Articulated Arm Measuring Instrument

Quality Engineering

Modern Precision has tried with no spare effort to increase quality and with years of experience, has developed a quality control method which is unique in its activeness and preventiveness. To ensure satisfying delivery to customers, Modern Precision has developed strict procedures from raw material purchase to finished product delivery, from workshop to lab, from manufacturing process analysis to rejected product analysis. Each procedure is monitored and followed one after another. For higher quality, any procedure that can possibly affect product quality has been taken into consideration.

Quality Engineering Process

-

IQC

-

LQC

-

FQC

-

OQC